The use of stirrups in reinforcement

Contents |

[edit] The role of stirrups in reinforced concrete beams

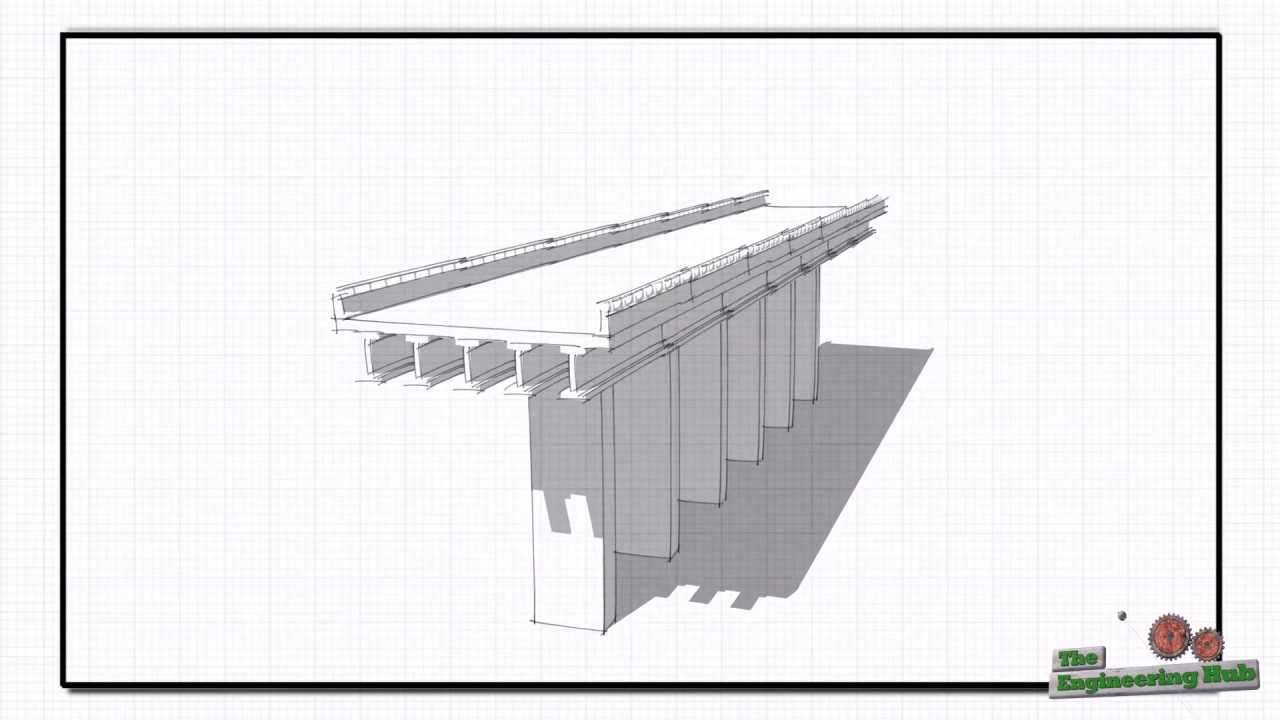

Concrete is seldom used without steel reinforcement in construction because of its tendency to crack and its inability to transfer tension loads. So, what is the purpose of transverse reinforcements, also known as stirrups? To understand this, we need to dive deeper into the load-carrying mechanics and the actual reason why stirrups are essential in concrete beams. The primary function of a beam is to transfer loads to the supports, allowing for open spaces. Beams are among the most common structural members found in various structures.

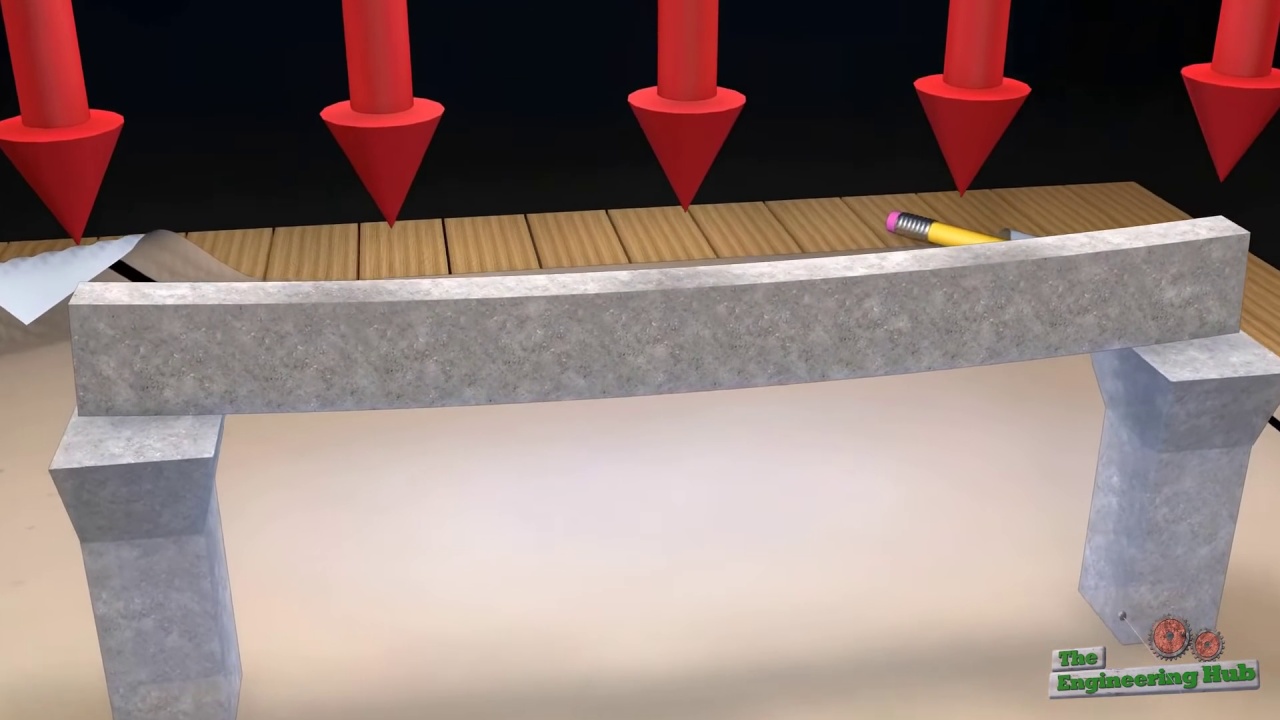

In this discussion, we'll focus on concrete beams under gravity loads. However, it's important to note that many of the concepts discussed here are applicable to all types of beams. Beams are typically subjected to bending, which causes stretching of the material on one side and crushing on the other side. The amount of stretching and crushing depends on factors such as the length, size, material of the beam, and the magnitude of the load. Among these factors, length is the most significant, making longer beams more susceptible to bending.

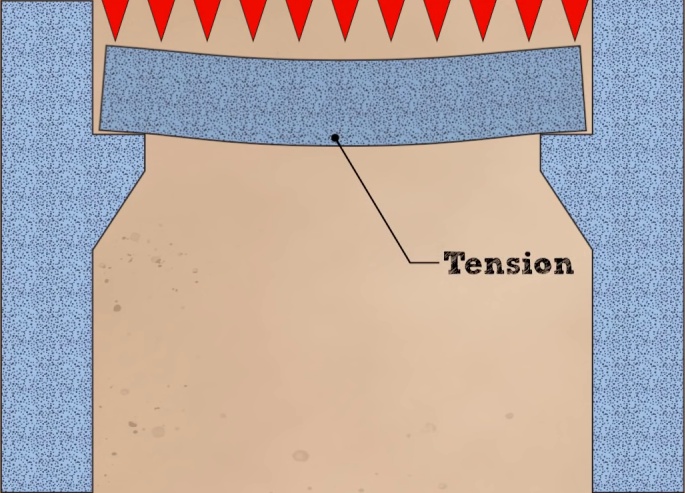

As the beam continues to bend, cracks may appear at the bottom side where the material is being stretched. Once a crack develops, the concrete loses its ability to carry tension loads. Consequently, the tension must be taken by the steel reinforcement within the beam.

[edit] Shear forces and the importance of steel reinforcement in concrete beams

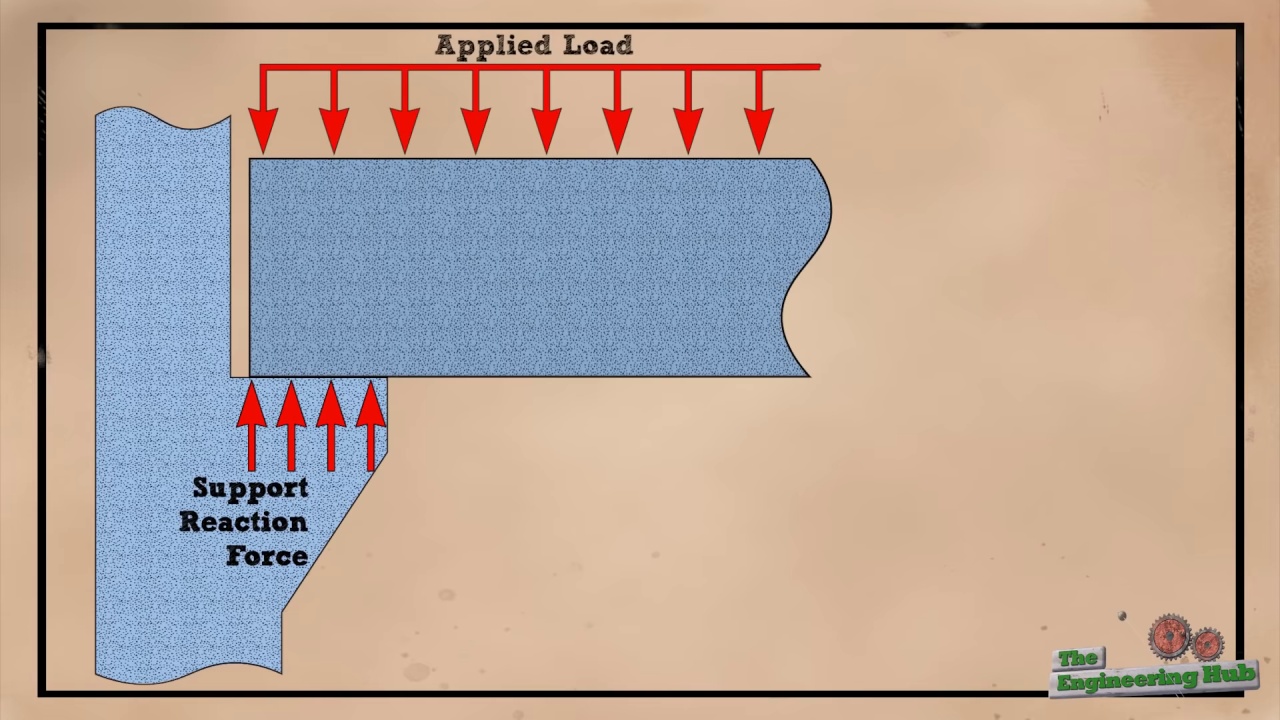

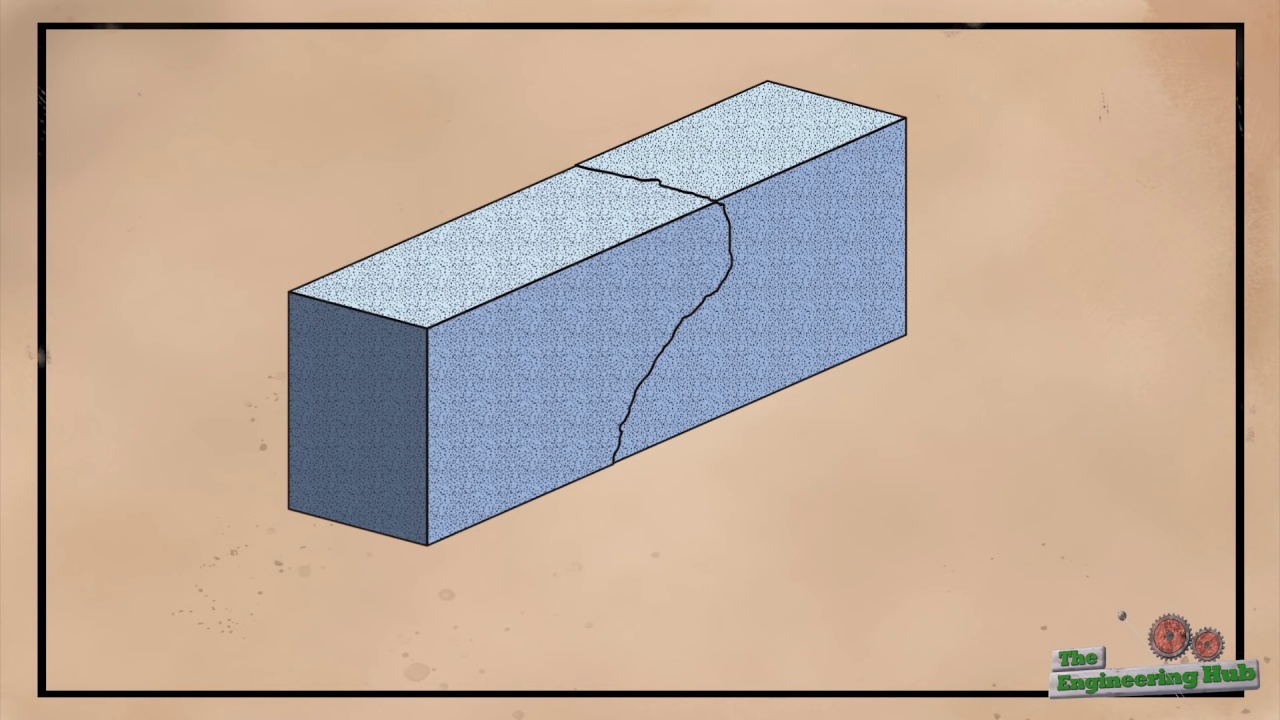

Besides stretching and compressing, the material in a beam also experiences shearing forces. These forces attempt to shear off the beam, as demonstrated in the image below. For simple beams, shearing forces are the highest near the supports due to the high forces exerted from the support, while they are zero at the mid-span of the beam. These forces are very destructive and usually cause sudden and brittle failure of the beam.

The bending and shear loads are the most important design considerations for a simple beam loaded concentrically. These forces guide the design of the beam in terms of size, amount of steel, and length. You might be wondering how a concrete beam resists these forces and why steel reinforcement is even necessary.

The strength of concrete as a material lies in its ability to resist compression forces, making it an ideal choice for columns or walls. However, concrete is notably weak when it comes to resisting tension forces. Engineers often assume its tension strength to be zero during design, as concrete is considered to be cracked in structural analysis, preventing the transfer of tensile forces. While cracked concrete does offer some minimal tension resistance, relying on this strength is risky and unreliable. As a result, engineers must reinforce the section of the structural member that is expected to experience tension. In the case of simple beams, this reinforcement is typically placed on the bottom side.

For more complex arrangements, steel reinforcement might be needed on both sides of the beam, especially when dealing with tension forces. For instance, a cantilever beam with the top material in tension would have the top part of the beam reinforced. Longitudinal rebar takes tension on the bottom, while concrete takes compression on the top. But what about stirrups?

Many people in construction believe that stirrups are only there to hold the longitudinal reinforcement in place. While this is true, it's not their main purpose. Stirrups, like longitudinal reinforcement, are also used to resist stresses that the concrete alone can't handle effectively. These stresses are caused by shear forces, which is why stirrups are often referred to as shear reinforcement.

Stirrups come into play when an inclined crack occurs in the beam. These cracks, known as shear cracks, are actually caused by tension forces – something we'll explore later. It's worth noting that these cracks are usually microscopic and often invisible to the naked eye.

The presence of stirrups is crucial in the design of concrete structures. When concrete cracks, tensile forces are no longer transmitted across the crack, leaving only the interlocking of the concrete aggregates to provide resistance. This interlocking force can be quite strong, offering between 33 to 50 percent of the shear resistance of a beam. However, as the crack widens, interlocking weakens and resistance drops, allowing the two sides of the crack to slide past one another. This sliding in granular materials results in motion perpendicular to the direction of the applied force.

At this critical point, stirrups come into play, preventing full separation and sliding of the concrete. They effectively halt the sliding motion and begin to carry the shear force that was once carried by interlocking. By doing so, stirrups ensure the structural integrity of concrete structures, even in the presence of cracks.

[edit] Shear capacity and crack propagation in concrete beams

Interlocking can become less effective as a result of crack widening, making it an unreliable factor in calculating the shear capacity of a beam. In fact, the only concrete shear resistance for regular cast-in-place beams comes from the uncracked concrete on the compression side. Since the intrinsic concrete shear stress is often insufficient for a safe design, engineers must determine the amount of reinforcement needed based on the applied shear forces and the width of the inclined crack.

To account for higher shear loads near the supports, stirrups are placed closely together, ensuring that several of them will be engaged within an inclined crack. Near the middle of the beam, where the shear forces are low, designers might reduce the spacing or completely eliminate the stirrups.

It's interesting to note that although shearing forces act perpendicular to the beam, the crack tends to follow a curved trajectory rather than a vertical one across the entire depth of the beam. This observation raises the question: why doesn't a beam crack vertically down across its entire depth?

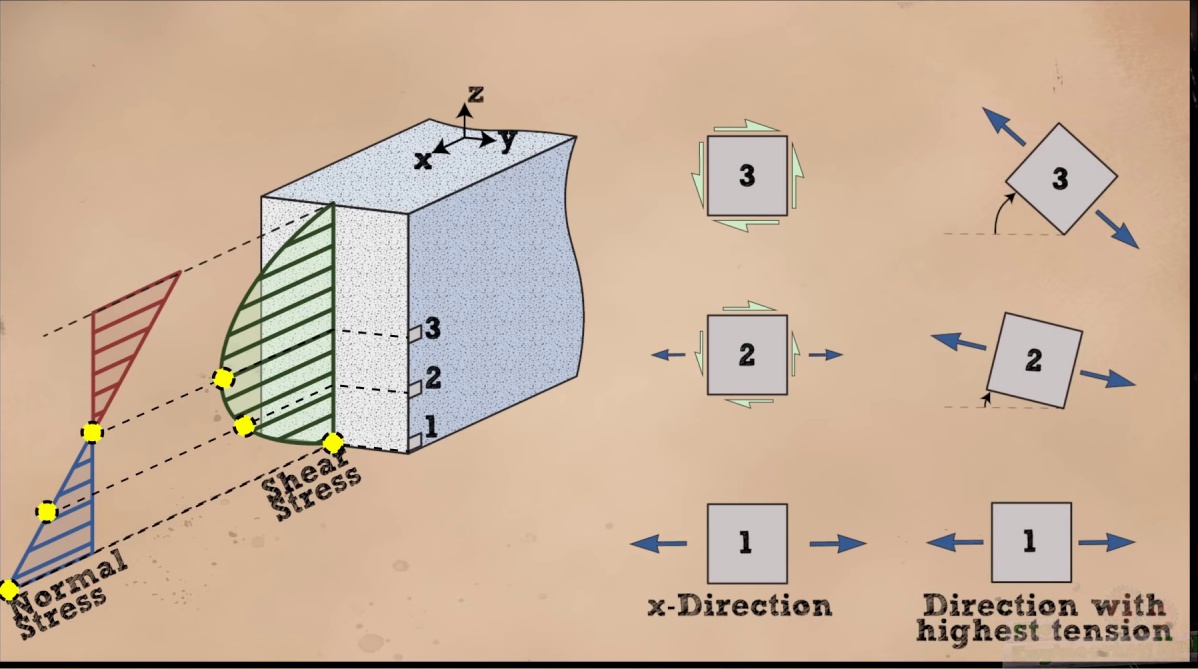

To understand the propagation of cracks in concrete, we need to delve into the complex stress states caused by combined loading. When a beam bends, its cross-section experiences both normal and shear stresses. The distribution of these stresses varies throughout the cross-section, as demonstrated in the example. To predict crack propagation, we must determine the direction in which the beam experiences the highest tension loads, as tension loads are responsible for cracking the concrete. This direction, called the principal direction, is where the material experiences no shear stresses, and all energy is stored in the normal stresses. The principal direction varies along the depth of the beam, as illustrated in the example. However, we won't go into detail on how to calculate this direction.

[edit] Stress transformation and crack propagation in beams

If you want to dive deeper into the topic, we recommend researching stress transformation and Mohr's circle. These concepts help explain why the highest tension stresses act in a particular direction, causing the crack to propagate that way. For instance, at the bottom of a beam, there are no shear stresses. As a result, the principal direction (also known as the direction of highest normal stresses) is already aligned along the length of the beam, which is why cracks initially appear vertical at the beam's bottom.

However, as the crack propagates towards the inner part of the beam, the shear stresses experienced by the material are no longer zero. This means that the direction with the highest normal stresses has changed. The principal direction now becomes slightly inclined, causing the crack to propagate along this inclined path. These stress states are the reason why cracks follow a curved trajectory near the ends of a simple beam. To address this issue, shear reinforcement is placed in those regions to provide additional support and prevent crack propagation.

I hope this has provided a useful introduction to the concept and application of shear reinforcing. I always enjoy engaging in discussions, so feel free to share your thoughts, ideas, or experiences related to this topic in the comments below. If you found this information helpful, consider subscribing to stay updated with more content like this. Your support is the easiest and most effective way to motivate me to produce more informative content. Thank you, and see you next time!

[edit] Related articles on Designing Buildings

- Carbon fibre.

- Concrete.

- Concrete-steel composite structures.

- Concrete vs. steel.

- Formwork.

- Grouting in civil engineering.

- Iron frames in textile mills.

- Metal fabrication.

- Prestressed concrete.

- Rebar.

- Reinforced concrete.

- Reinforcement detailing.

- Structural steelwork.

- Substructure.

- Stainless steel.

- Types of column.

- Weathering steel.

[edit] External references

Material from the Video: "The actual reason for using stirrups explained", prepared by "The Engineering Hub".

Featured articles and news

Latest Build UK Building Safety Regime explainer published

Key elements in one short, now updated document.

UKGBC launch the UK Climate Resilience Roadmap

First guidance of its kind on direct climate impacts for the built environment and how it can adapt.

CLC Health, Safety and Wellbeing Strategy 2025

Launched by the Minister for Industry to look at fatalities on site, improving mental health and other issues.

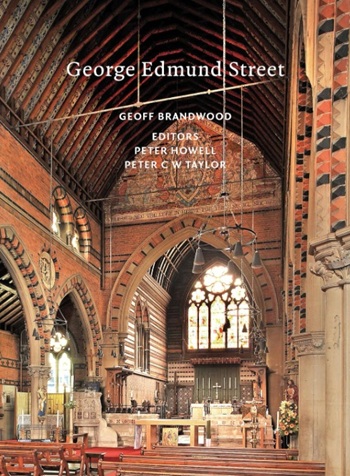

One of the most impressive Victorian architects. Book review.

Common Assessment Standard now with building safety

New CAS update now includes mandatory building safety questions.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.